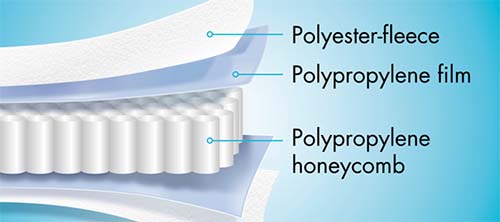

Polypropylene Honeycomb Core

The basic raw material for producing the honeycomb is polypropylene, a thermoplastic, recyclable material from the polyolefin group.

It is an ideal component for any lightweight assembly, as it is extremely light but very strong. It provides high stability at a low weight and is resistant to both heat and corrosion.

The cells within polypropylene honeycomb have tabular form and provide superior stability

Polypropene honeycomb is available with or without a non-woven polyester fabric for greater bonding. With non-woven polyester fabric, pp honeycomb sheet can be easily further bonded with FRP, wood grain sheet, aluminium plate, stainless steel sheet, marble sheet, rubber sheet etc.

Polypropylene honeycomb is also with or without a film barrier under the polyester fabric to limit the amount of resin consumption

Characteristics

- Extremely Light

- High strength to weight ratio

- Corrosion, Rot and Fungi resistant

- Chemical and moisture resistance, Low water absorption

- Reduces noise and vibrations

- Highest dimensional stability due to precise cutting

- Can be thermally moulded. Temperature use up to 180 degree F

- Recyclable

SPECIFICATION

Type | PP Honeycomb Core |

Standard Dimension (mm) | 1220 * 2440 |

Core Thickness (mm) | 5 to 100 |

Standard Cell Size(mm) | 8, 10 and 12 |

Colour | White |

APPLICATIONS

- Commercial vehicle construction

- Boat and ship building due to low water absorption properties

- Rail vehicle construction

- Van body for logistics and express, mobile house, package, and caravan etc.

- Air filters to reduce corrosive gas emissions

- Flat surface for waterjet cutting machines

- Construction

- Wind power systems